Gallery

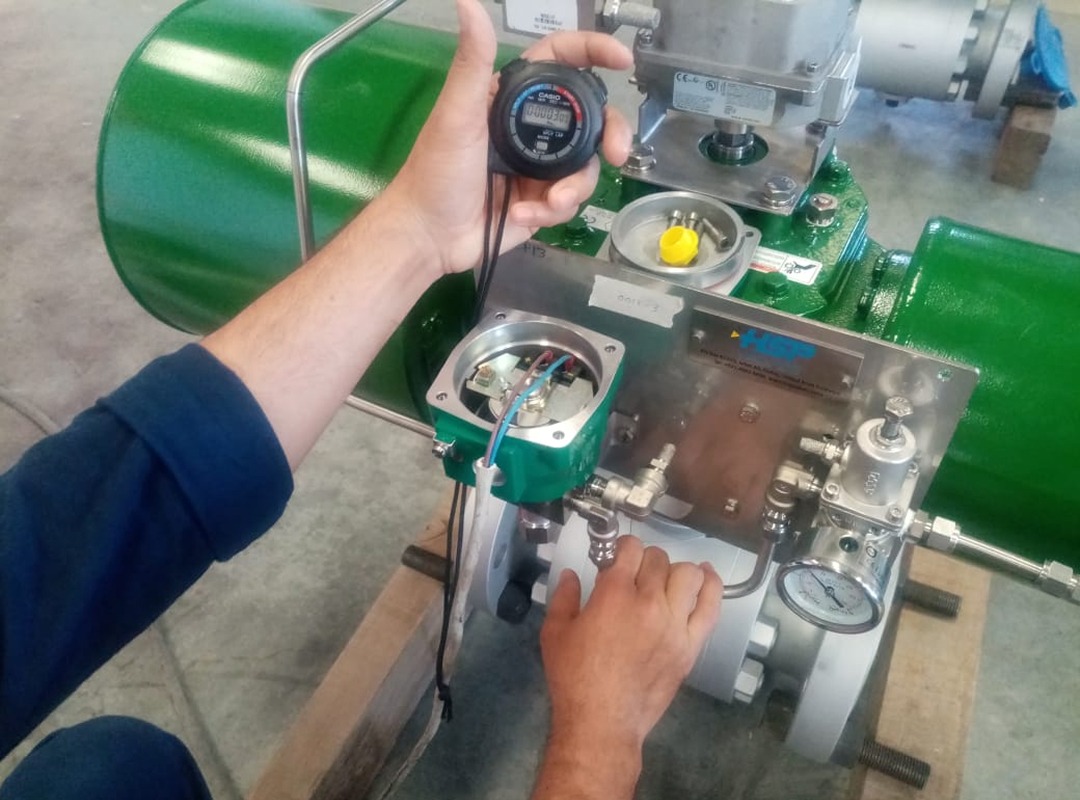

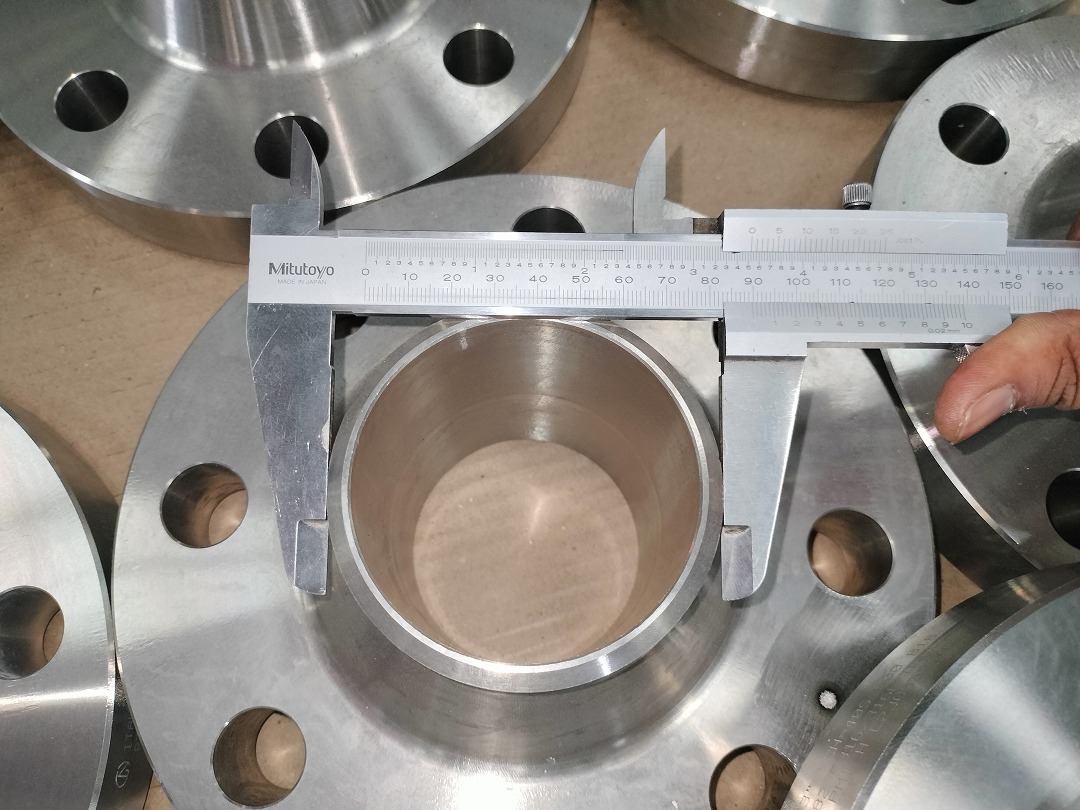

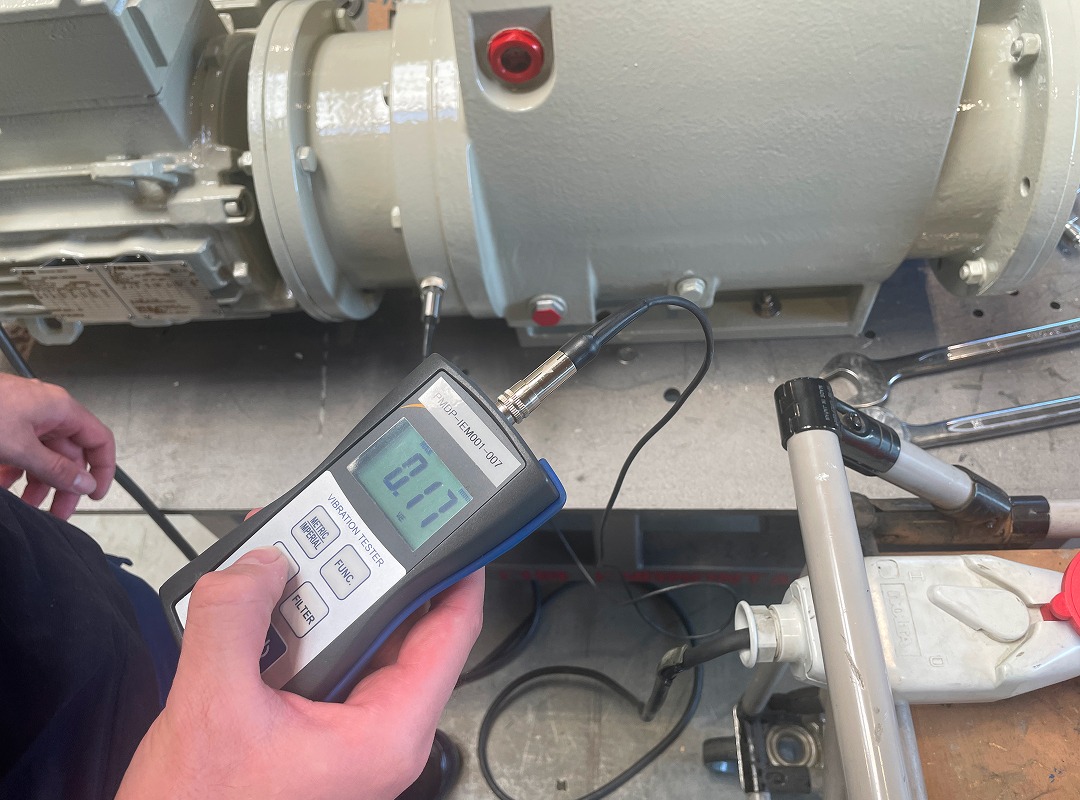

Mechanical Inspection

Mechanical inspections are crucial for ensuring the safety, reliability, and performance of machinery and equipment. These inspections can be conducted on various types of mechanical systems, including industrial machinery, automotive components, and structural elements. common types of mechanical inspections are Visual inspections, Welding inspections, Non-Destructive Testing (NDT), Performance Testing, Maintenance inspections, Safety Inspections, Lab testing, etc, MCG have expertise in Process line pipes Tube, Fittings, Fitting Flanges, Valves, Expansion joints, Bolt/Nut, Gasket, Steam /Air Trap, Strainer Silencer, Sample Cooler, GRE, FRP Pipes, Vessels Tanks Reactors, Towers, Heat Exchangers Air Fin Coolers, HRSG,

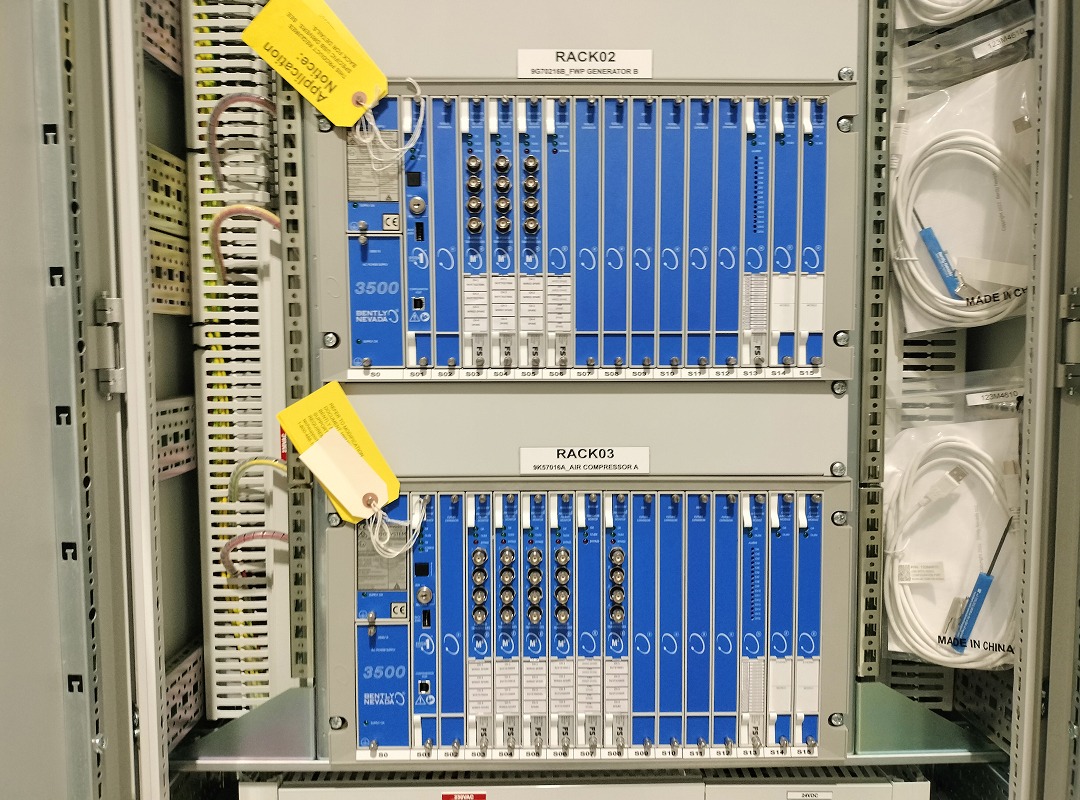

Electrical Inspection

An electrical inspection is a systematic examination of electrical systems, equipment, and installations to ensure they are safe, functional, and compliant with relevant standards and regulations, some key aspects of electrical inspections are Visual Inspection, Grounding and Bonding, Load Testing, Factory acceptance test, Site acceptance test, Integrated test, MCG have expertise on test in Transformer, Switchgears and MMC, Motors, Generator, Reactors, Resistor, Illumination Fixtures, UPS, Battery and Battery Charger, DCS, Solar panels, FGS system, LCR FAT, ESD, F&G , Solar Energy FAT, Power Plant FAT , Telephone Paging System, General Paging System, Auto Paging System, Wireless Paging System, Telephone System, Direct Phone, Inter Phone System, ICSS system, Etc

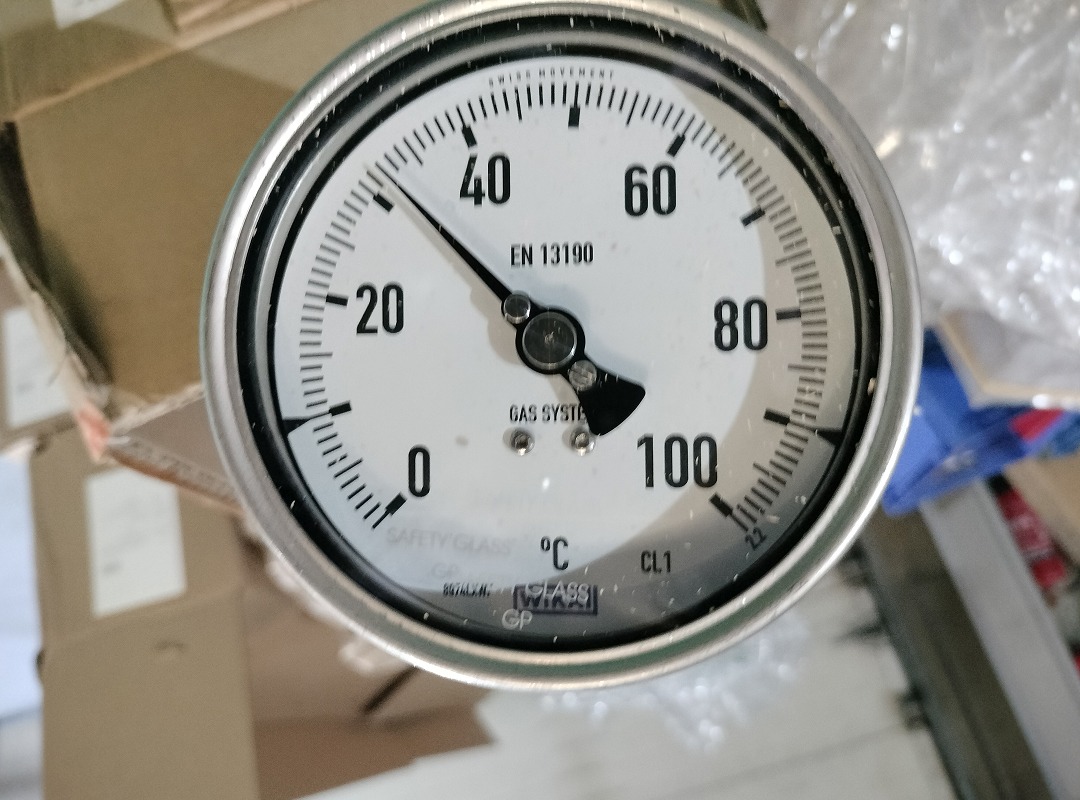

Instrumentation Inspection

Instrumentation inspection involves examining and testing various instruments and systems to ensure they are functioning correctly and safely. This type of inspection is crucial in industries that rely heavily on accurate measurements and control systems. Here are some key aspects of instrumentation inspection: Visual Inspection, Installation Check, Wiring and Electrical Connections, Display and Output Signal Check, Range and Calibration, Loop Testing, MCG have expertise on test in Transmitter Recorders Controller Metering System Probers, TW, TG, TT, PG,PT, LG, LT Manifolds, etc

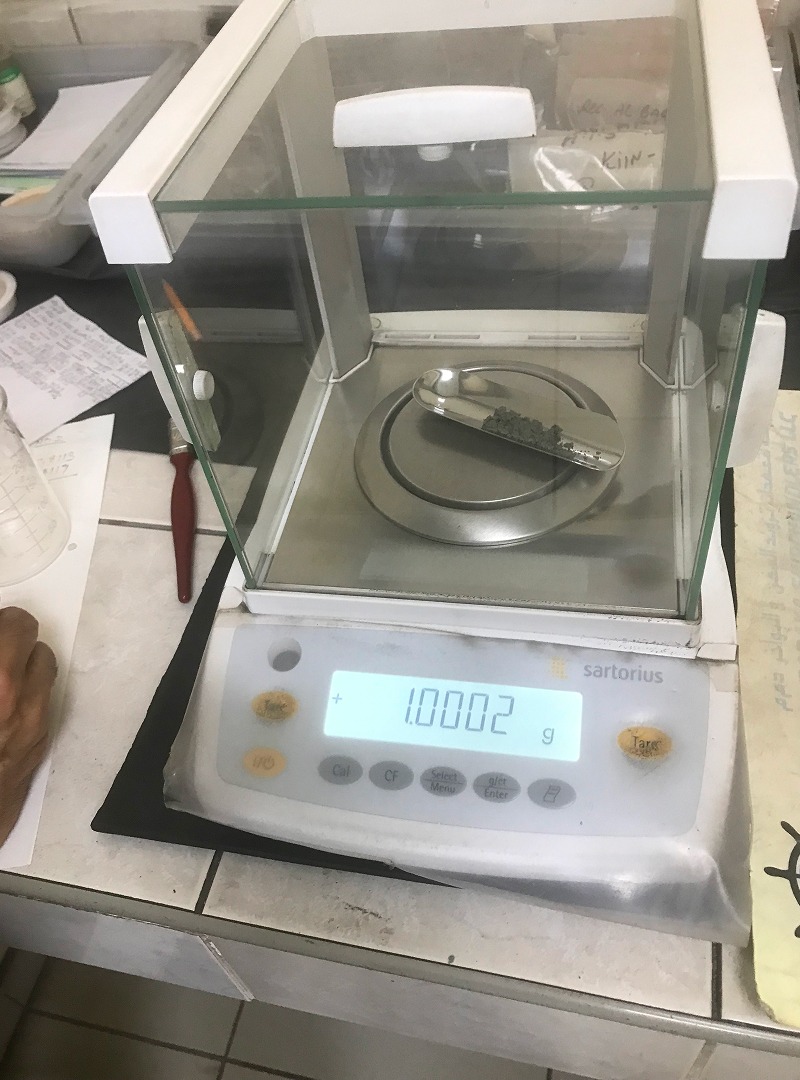

Civil Inspection

Civil inspection involves a thorough examination of construction projects to ensure they meet safety standards, structural integrity, and compliance with regulations. Some key aspects of civil inspections are Structural Integrity, Foundation Inspection, Material Quality, Drainage Systems. MCG have expertise on Concrete test, Soil test, Checking the quality of cement, fine Aggregate & coarse Aggregate, Terrazzo Tiles, Trail mix of concrete

Painting and Coating Inspection

Painting and coating inspection ensures that coatings are applied correctly and provide the intended protection and aesthetics. some key aspects of this type of inspection are Surface Preparation, Coating Material Verification, Application Process, Dry Film Thickness (DFT) Measurement, Adhesion Testing, Holiday Detection and Visual inspection, MCG have BGAS inspector with experience in Cross cut Test, Pencil Test, Adhesion Test, Peel off Test, DFT Check, BEND Test, IMPACT Test etc

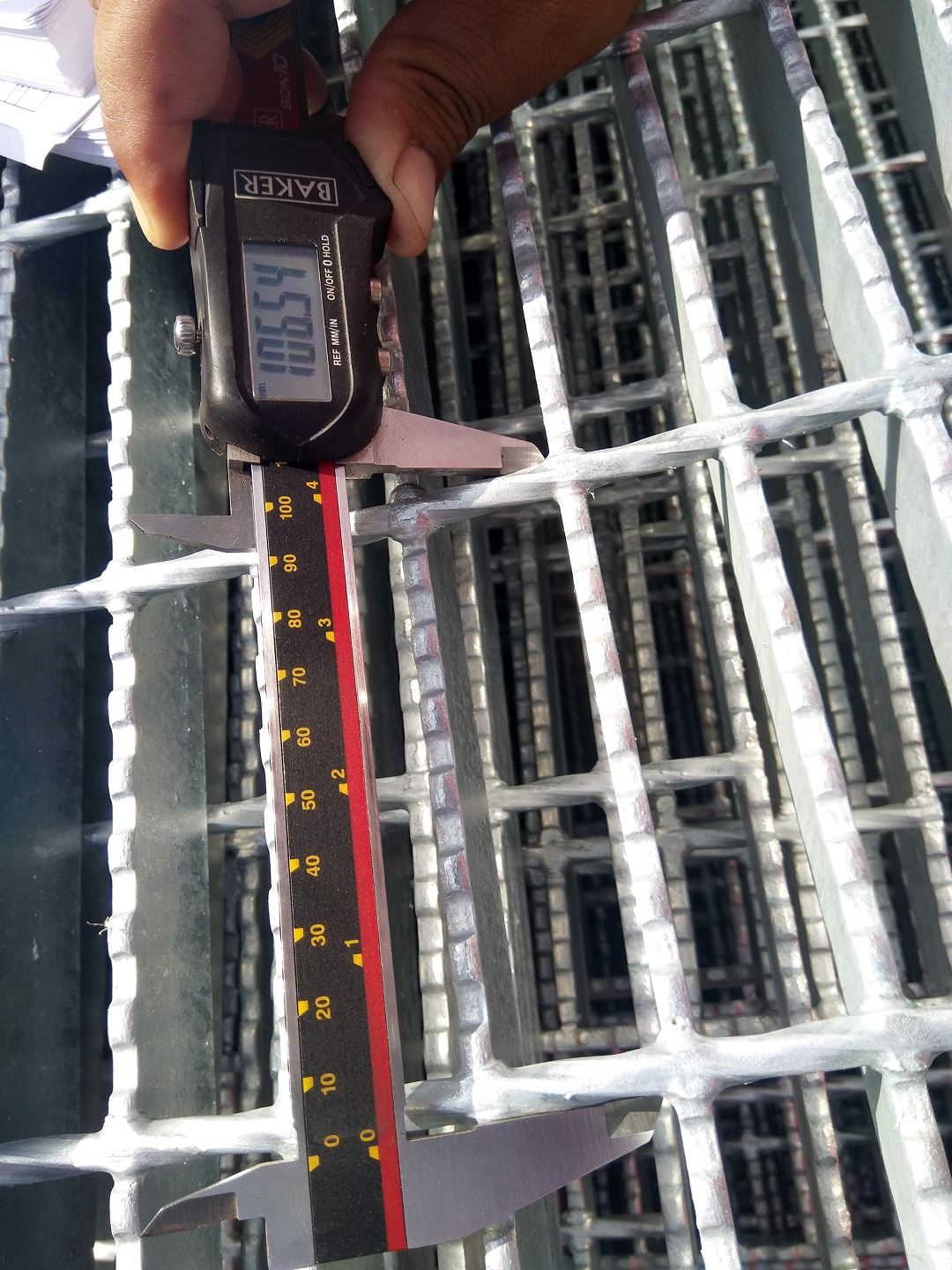

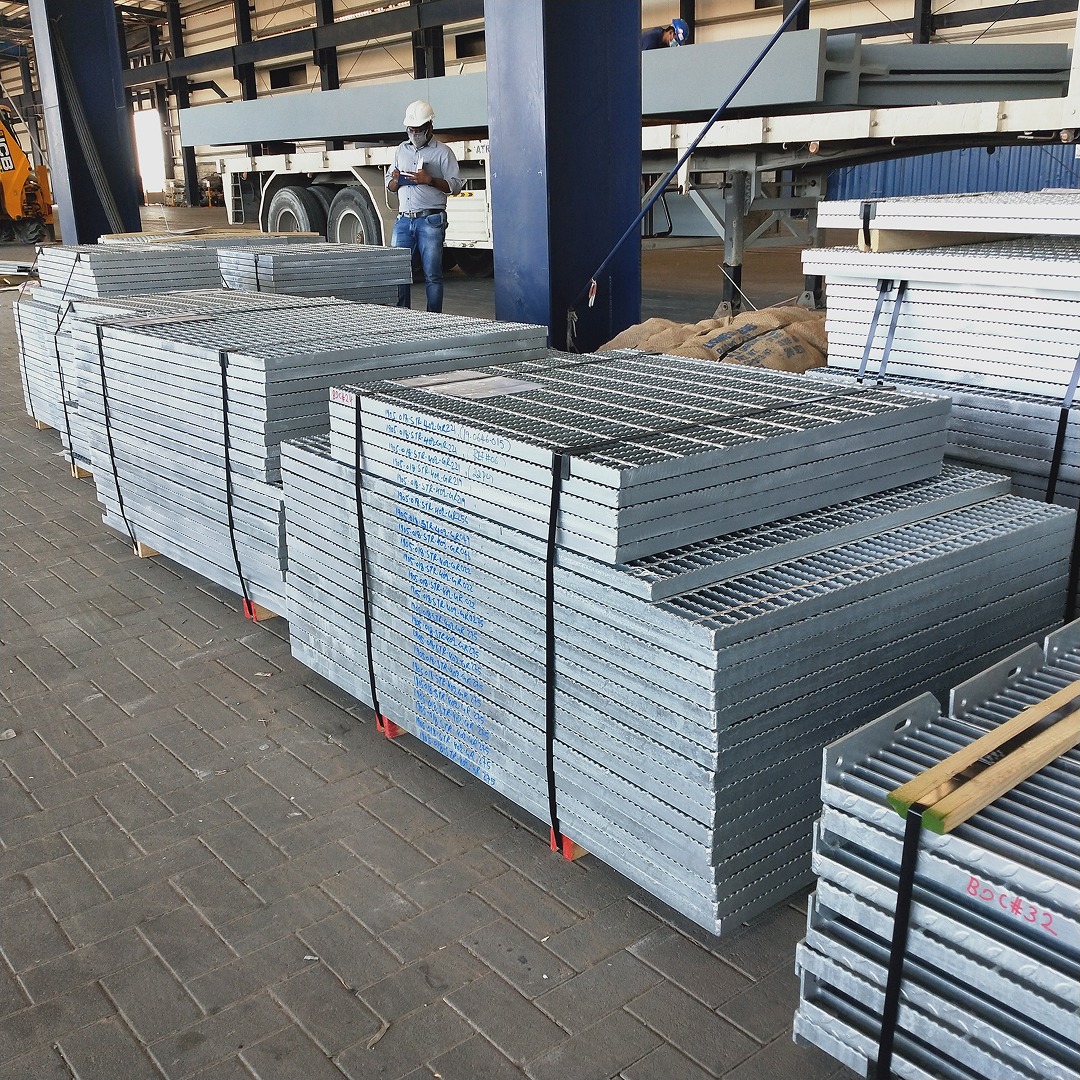

Material Inspection, Packing, marking, Loading and pre shipment Inspection

Packing, marking, Loading is a crucial process in supply chain logistics to ensure that goods are safely and correctly loaded into shipping containers or vehicles, some key aspects of Packing, marking, Loading are Quantity and Quality Check, Packaging Inspection, Loading Supervision, Condition of Containers and Vehicles, Documentation, Loading procedure etc

Pre-inspection Meeting, Expediting, Project management and Supervision, Inspection Coordination and Data Controlling

The purpose of pre-inspection meeting is to discuss with Vendor’s representative the inspection topics such as range of inspection, communication channel, checking the Vendor’s quality system and other inspection related matters, In addition, at the time of Vendor’s shop visit itis confirmed that they fully understood and will comply with purchase order requirements, Expediting-This is to compare the progress of activities with a predetermined time schedule or critical path network, This allows detection and analysis of activities which might cause delays, assist in suggesting constructive solutions in order to meet the dates of pre-established programs, and inform the client of the actual situation existing at the manufacturers facilities and of all decisions taken or suggested regarding the time schedule, MCG has done small scale projects with positive results and client satisfaction, MCG have Coordinators for local and foreign inspection who is doing proposal, review, verification, arrangement and data controlling